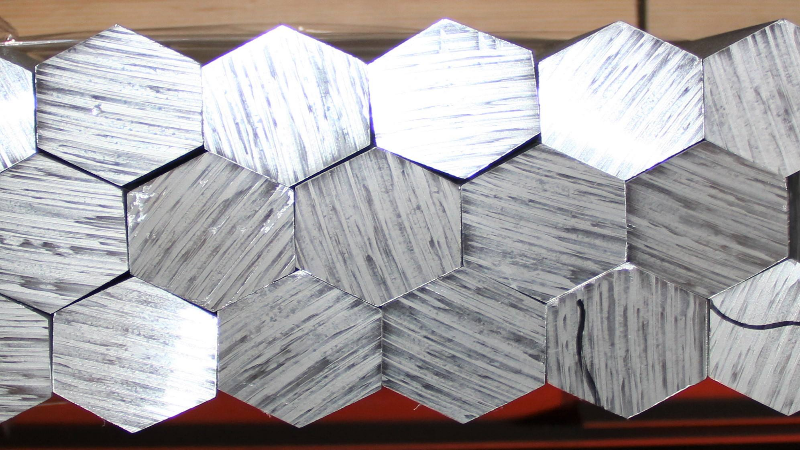

When discussing materials that are used to create household objects and appliances, aluminum is always among the top contenders. Lightweight and durable, it is an ideal choice for several products. But once aluminum has undergone the cast process, it gets new exciting features that make it beloved by designers, engineers, homeowners, and renovators alike. Cast aluminum is a metal that is produced through a process where molten metal is poured into a mold to create the final product.

In this blog post, we will discuss a few ways aluminum casting companies are profiting.

Outdoor Furniture

High-quality cast aluminum is perfect for outdoor furniture because of its ability to withstand harsh weather conditions. With proper maintenance, such as routine cleaning and occasional coat of wax, cast aluminum furniture resists rust and corrosion, making it hardy and durable. Its quality and design offer an elegant and classy look to any backyard or patio.

Cooking Utensils

Cookware is a fundamental item in every kitchen, and it offers great cooking performance. With its exceptional ability to distribute heat across the pan’s surface, cookware made of cast aluminum (CA) guarantees fast and even cooking, consuming less energy than other materials. This material’s lightweight feature makes it easy to handle in the kitchen, making cooking a breeze.

Auto Parts

The use of CA in automotive parts such as engine blocks, pistons, and radiator cores has been on the rise in recent years. With its superior strength, high resistance to heat, corrosion, and rust, CA parts ensure optimal performance and efficiency in vehicles.

Safety Equipment

CA is used in manufacturing safety equipment including helmets and fire-resistant clothing because of its strength and durability. Also, it’s lightweight, making it easy for wearers to move across different terrains, in and out of dangerous places, which makes it a popular material in the construction and mining industries.