Aluminum is one of the most common elements found on the planet and is also frequently mined. Aluminum itself isn’t particularly strong, but in the form of an alloy, it can match strength with steel. Alloys are also easy to process and come in the form of multiple products and shapes, including extruded bar stock.

What is Aluminum Bar?

Similar to children’s play clay, aluminum bar stock is manufactured by pushing heated billet through a die in a specified shape, resulting in long bars of aluminum. Die shapes can produce multiple bar profiles, including aluminum square bar or rectangle bar or complex heat sinks and multi-hollow extrusions.

The Benefits of Extruded Aluminum

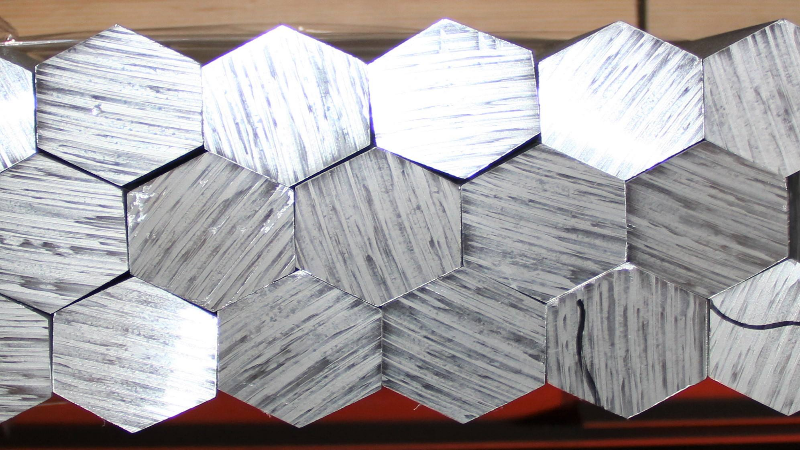

The term bar stock isn’t limited to aluminum square bar or rectangle bar. It also covers aluminum hex, round stock, tubing, custom shapes and other lineal products. The process of extrusion has the potential to simplify the manufacture of a wide variety of product sizes and shapes while cutting down on material costs, machining time, tooling wear and production time.

When to Use Custom Shapes

While aluminum extrusion is an optimal way of producing parts in general, it’s also an ideal way to obtain shapes that aren’t frequently stocked. Any common shape at non-standard sizes, such as 3.80″ aluminum square bar, or hollow shapes with complex interiors, can be produced with custom extrusion while saving money and time.

Leading Providers of Aluminum Bar

By paying attention to customer needs and changes in the market and keeping abreast of current technology, a family-owned and leading distributor of aluminum products with more than 80 years in business can promptly provide finished quality goods from top suppliers while also offering precision sawing equipment, sawing services and outside processing along with top-level customer service.